-

Your Partner for RF,

Microwave and High Voltage

Power Systems

-

Spacecraft Assembly,

Integration

& Testing (AIT)

-

Cable Harnessing

RF Space

Sub Systems

Fabrication Assembly and Testing

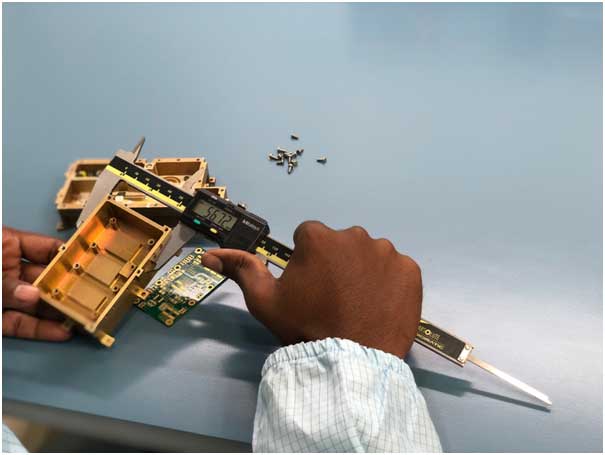

Aidin holds a State of the Art Class 10000 clean room that is equipped with production equipment including conformal coating. Our facility is audited and certified by ISRO for onboard fabrication and assembly. Our team includes ISRO Certified Technicians and QC inspectors to perform card assembly.

- COMPLETE DOCUMENTATION FOR TRACKING AND TRACEABILITY

- FABRICATION AND TESTING TO CUSTOMER SPECIFICATION

- WORKMANSHIP STANDARDS AS PER ISRO PAX-300

Assembly Integration and Testing of Spacecraft

We have been actively involved in building End-to-End satellites in consortium with few other aerospace players. We have successfully built Indian Regional Navigational Satellite Systems IRNSS 1H and 1I and it was successfully launched subsequently. In total we have built four satellites for ISRO, all of them have been successfully launched. We work on three categories of satellites I-1K/Small Satellite, IRS/I-2K/I-3K Bus, I-4K Bus and above.

The qualified spacecraft subsystems hardware flows into the AIT Clean room facility for electrical & mechanical integration activities in a sequential manner. The completely integrated/assembled satellite undergoes a series of environmental tests including Thermovac test, Vibration test, Acoustic test, Compact antenna ranging test, physical parameter measurements, Dynamic tests etc. that ultimately qualifies the spacecraft for launch. Satellite AIT activities is an involved process demanding multi-disciplinary expertise. Typically, experienced workforce with domain expertise in mechanical, electrical/electronics, computer science areas are needed to carry out satellite AIT activities.

Four main activities we do in Assembly Integration & Testing (AIT) are:

- Spacecraft Preparations

- Propulsion System, Payload Integration & Testing

- Assembled Mode Integrated Spacecraft Tests (IST)

- Thermo Vacuum, Acoustic, Vibration, EMI/EMC Tests

End-to-End Services

We have capability and expertise to build and develop End-to-End solutions of a space sub module which includes:

- Sourcing of Space Grade components

- PCB blank manufacturing by our Partners, who are ISRO approved vendors

- Mechanical chassis fabrication as per approved ISRO drawings by our partner, an ISRO approved vendor

- Incoming Goods Inspection in our facility

- Fabrication, Assembly & Testing of the Space Sub module

- Package wiring Integration & Testing

- Environmental tests including EMI/EMC, Thermovaccum tests

Details of work

The details of works to be carried out can be broadly listed out as follows:

- PCB layout design work, which includes:

- Creation of device footprints and part library

- Schematic capture

- ERC/DRC setting

- Component placement

- PCB Layer stackup design and finalizing controlled impedance requirements

- Board routing

- DRC and netlist checks

- Layout completion

- Post processing of fabrication data

- PCB Simulation, which includes:

- Signal Integrity Analysis

- Power Integrity Analysis

- Thermal Analysis

- EMI/EMC Analysis

- Layout modification based on simulation results

- Modification in old and previously completed PCB layouts

PCB Design Services

Aidin with its partners supports Engineering design services in the areas of RF design, Antenna design, IC and SIP Package design, RF and Antenna testing, EM CAD tool based simulations that include SI analysis, PI analysis, EMI/EMC analysis.

we also provide value added services like PCB fabrication and assembly, IC Package assembly services, Mechanical and ID design services, Rapid prototyping services, multiphysics simulations for customers looking for one stop solution for all their requirements

With our experienced Engineering team with rich expertise in having carried out multiple successful designs in RF/Antenna/IC Packaging/PCB domain areas

We offer Engineering design services with guaranteed customer satisfaction, highest quality standards at affordable cost, flexible business models and requirements met on time

Mechanical Design Services

To leverage growing demand for aerospace machining capacity and India’s increasing offset requirement, Aidin has partnered with Mechanical design companies. Our partners are AS 9100 Rev. D, IATF 16949: 2016 and ISO 9001:2015 certified, specialising in low volume-high mix machining for the aerospace and other industries.

OFFSET MANAGEMENT

Aidin has been audited and licensed by Indian MOD for offset Sub-System Manufacturing. We have also been chosen as the Primary Sourcing Partner by major US Defense contractor for managing their India offset Programs.

Single point of contact serving as Tier-1 Supplier

Complete logistics support

Tier-2,3.. Vendor coordination

Classified as MSME for Offset Credit Multipliers